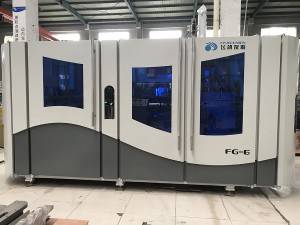

PET Lub raj mis tshuab tshuab

Nug tam sim noFG series PET Lub raj mis tshuab tshuab

FG series PET lub raj mis tshuab tshuab sau cov qhov khoob hauv thaj tsam ntawm kev kub ceev linear tshuab tshuab.Tam sim no, Tuam Tshoj linear ib leeg-pwm ceev tseem nyob ib puag ncig 1200BPH, thaum thoob ntiaj teb max ib leeg-pwm ceev tau mus txog 1800BPH.High-speed linear tshuab tshuab cia siab rau imports.Raws li qhov xwm txheej no, Faygo Union Machinery tau tsim Tuam Tshoj thawj zaug kev kub ceev linear tshuab tshuab: FG series lub raj mis tshuab tshuab, nws ib leeg-pwm ceev tuaj yeem ncav cuag 1800 ~ 2000BPH.FG series lub raj mis tshuab tshuab suav nrog peb tus qauv tam sim no: FG4 (4-kab noj hniav), FG6 (6-kab noj hniav), FG8 (8-kab noj hniav), thiab qhov siab tshaj plaws yuav yog 13000BPH.Nws yog tsim los ntawm nws tus kheej kiag li, muaj peb tus kheej txoj cai kev txawj ntse, thiab tau txais ntau tshaj 8 lub teb chaws patents.

Lub tshuab no yog nruab nrog tsis siv neeg ua haujlwm thauj khoom thiab lub raj mis unloading system.Nws muaj feem xyuam rau tag nrho cov duab ntawm cov dej haus fwj, carbonated fwj thiab kub filling fwj.FG4 yog tsim los ntawm peb lub modules: prefrom of elevator, ua unscrambler thiab host machine.

FG series lub raj mis tshuab tshuab yog lub cim tshiab ntawm linear tshuab tshuab, txawv los ntawm nws txoj kev kub ceev, tsis tshua muaj zog thiab qis compressed cua noj, featured los ntawm cov qauv zoo heev, me me chaw ua hauj lwm, tsis tshua muaj suab nrov thiab siab stability, lub caij no conforms rau lub teb chaws. haus dej huv cov qauv.Lub tshuab no cim lub siab tshaj plaws ntawm lub teb chaws linear tshuab tshuab.Nws yog lub raj mis zoo tshaj plaws ua khoom siv rau cov lag luam nruab nrab thiab loj.

FG Series Khoom Zoo

1. Servo tsav tsheb thiab cam txuas tshuab ntu:

Qhov tshwj xeeb cam txuas qhov sib txuas ua ke ntawm kev txav ntawm pwm-qhib, pwm-xauv thiab hauv qab pwm-nce hauv ib qho kev txav, nruab nrog kev kub ceev servo tsav tsheb uas zoo heev txo lub voj voog ntawm tshuab thiab nce lub peev xwm.

2. Me me ua haujlwm nyob deb ntawm cua sov

Lub qhov cub hluav taws xob hauv qhov cub cua sov yog txo rau 38 hli, piv nrog cov pa cua sov qhov cub nws txuag tau ntau dua 30% hluav taws xob noj.

Nruab nrog cua cycling system thiab redundant heat discharge system, nws ua kom qhov ntsuas kub tsis tu ncua ntawm thaj chaw cua sov.

3. Ua haujlwm zoo thiab mos ua haujlwm inlet

Los ntawm teb thiab mos preform inlet system, qhov ceev ntawm prefom pub yog guaranteed lub caij no, lub caj dab preform yog zoo tiv thaiv.

4. Modularized tsim conception

Kev siv lub tswv yim tsim qauv modularized, ua kom yooj yim thiab txuag nqi rau kev saib xyuas thiab hloov cov khoom seem.

Technical parameter

| Qauv | FG4 | FG6 | FG8 | Lus ceeb toom | ||

| Pwm Number (thooj) | 4 | 6 | 8 | |||

| Peev xwm (BPH) | 6500-8000 | 9000-10000 | 12000-13000 Nws | |||

| Lub raj mis specification | Max ntim (mL) | 2000 | 2000 | 750 | ||

| Max qhov siab (mm) | 328 | 328 | 328 | |||

| Round lub raj mis max txoj kab uas hla (mm) | 105 | 105 | 105 | |||

| Square raj mis max kab pheeb ces kaum (mm) | 115 | 115 | 115 | |||

| Preform specification | Tsim nyog lub raj mis lub caj dab (mm) | 20—25 | 20—25 | 20—25 | ||

| Max preform ntev (mm) | 150 | 150 | 150 | |||

| Hluav taws xob | Tag nrho lub zog installation (kW) | 51 | 51 | 97 | ||

| Cua sov qhov cub tiag fais fab (kW) | 25 | 30 | 45 | |||

| Voltage / zaus (V / Hz) | 380(50 Hz) | 380(50 Hz) | 380(50 Hz) | |||

| Compressed cua | Siab (bar) | 30 | 30 | 30 | ||

| Cov dej txias | Pwm dej | Siab (bar) | 4-6 | 4-6 | 4-6 | Dej chiller (5HP) |

| Kev tswj qhov kub thiab txias (° C) | 6—13 | 6—13 | 6—13 | |||

| Qhov cub dej | Siab (bar) | 4-6 | 4-6 | 4-6 | Dej chiller (5HP) | |

| Kev tswj qhov kub thiab txias (° C) | 6–13 | 6–13 | 6–13 | |||

| Tshuab specification | Tshuab dimension (m) (L * W * H) | 3.3 X 1 X 2.3 | 4.3 X 1 X 2.3 | 4.8 X 1 X 2.3 | ||

| Tshuab hnyav (Kg) | 3200 | 3 800 | 4 500 | |||

Cov khoom pom zoo

Ntau +- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu