Nyob rau hauv lub realm ntawm plastics ua, extruders ua lub luag hauj lwm tseem ceeb hauv shaping thiab transforming polymers rau hauv ntau yam khoom. Ntawm ntau hom extruder, conical ntxaib ntsia hlau extruders (CTSEs) thiab ib qho ntsia hlau extruders (SSEs) sawv tawm raws li kev xaiv tseem ceeb. Thaum ob qho tib si ua haujlwm rau lub hom phiaj ntawm kev ua cov polymer, lawv muaj cov yam ntxwv sib txawv thiab muaj peev xwm ua rau lawv haum rau kev siv sib txawv. Cov lus qhia dav dav no nkag mus rau hauv lub ntiaj teb ntawm CTSEs thiab SSEs, tshawb nrhiav lawv cov yam ntxwv tshwj xeeb, qhov zoo, thiab cov ntawv thov uas lawv ua tau zoo.

Conical Twin Screw Extruders: Lub Symphony ntawm Kev Sib Tw thiab Kev Ua Tau Zoo

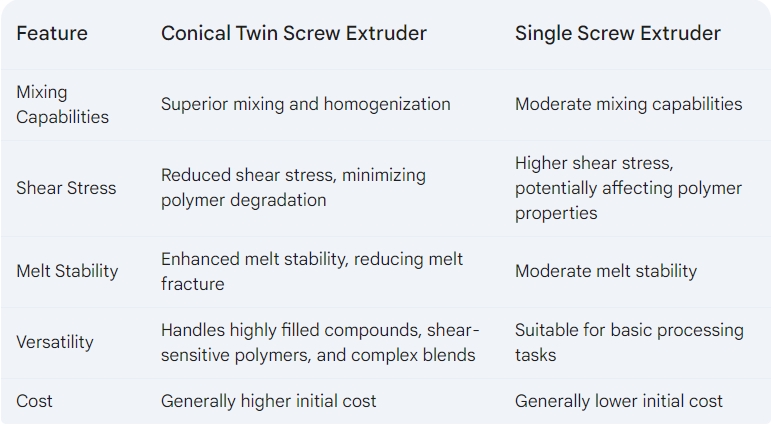

Conical ntxaib ntsia hlau extruders (CTSEs) muaj npe nrov rau lawv qhov tshwj xeeb sib xyaw muaj peev xwm thiab ntau yam hauv kev tuav cov ntawv thov. Lawv lub ntsiab lus txhais yog lub conical chim tsim, qhov twg lub thoob txoj kab uas hla maj mam txo mus rau qhov kawg paug. Qhov tshwj xeeb geometry no txhawb kev sib xyaw ua ke thiab homogenization ntawm polymer blends, additives, thiab fillers, kom ntseeg tau tias ib qho kev faib tawm ntawm cov ntaub ntawv thoob plaws hauv lub yaj.

Qhov zoo ntawm Conical Twin Screw Extruders:

Txhim khu kev sib xyaw thiab Homogenization: CTSEs ua tau zoo ntawm kev tsim cov khoom lag luam zoo nrog cov khoom sib xws thiab kev ua haujlwm, ua rau lawv zoo tagnrho rau cov ntawv thov uas xav tau kev sib xyaw ua ke.

Txo Cov Kev Nyuaj Siab: Lub conical tsim minimizes shear stress ntawm lub polymer yaj, tiv thaiv polymer degradation thiab xyuas kom meej cov khoom zoo, tshwj xeeb tshaj yog rau shear-sensitive polymers.

Txhim kho Melt Stability: CTSEs txhim khu kev ruaj ntseg yaj, txo qhov kev pheej hmoo ntawm cov tawg tawg thiab ua kom cov txheej txheem du, zoo ib yam extrusion, tseem ceeb heev rau kev tsim cov khoom nrog qhov ntev thiab cov khoom nto.

Versatility for Demanding Applications: CTSEs tuav cov khoom sib xyaw ua ke, shear-sensitive polymers, thiab complex polymer blends, ua rau lawv tsim nyog rau kev thov xws li hlau thiab cable rwb thaiv tsev, kho mob plastics, automotive plastics, ntim, thiab compounding / masterbatching.

Ib leeg ntsia hlau Extruders: Simplicity thiab nqi-zoo

Ib leeg ntsia hlau extruders (SSEs) sawv cev rau cov neeg ua haujlwm ntawm kev lag luam plastics, muab cov kev daws teeb meem yooj yim thiab raug nqi rau ntau yam kev siv. Lawv tsim nta ib tug ntsia hlau tig nyob rau hauv lub cylindrical chim, conveying, melting, thiab shaping lub polymer.

Qhov zoo ntawm Single Screw Extruders:

Yooj Yim Tsim thiab Ua Haujlwm: SSEs muab cov qauv tsim thiab kev ua haujlwm yooj yim, ua rau lawv yooj yim los tswj thiab tsis tshua muaj kev cuam tshuam.

Nqi-Effectiveness: SSEs feem ntau pheej yig dua li CTSEs, tshwj xeeb tshaj yog rau cov ntawv thov uas nyuaj sib xyaw lossis tuav cov khoom nyuaj tsis tas yuav tsum tau ua.

Tsim nyog rau Kev Ua Haujlwm Yooj Yim: SSEs ua tau zoo ntawm cov haujlwm yooj yim polymer ua haujlwm xws li pelletizing, compounding, thiab tsim cov ntaub ntawv yooj yim, ua rau lawv tsim nyog rau cov nqi siv hluav taws xob.

Xaiv Txoj Cai Extruder: Ib Daim Ntawv Thov thiab Xav Tau

Qhov kev txiav txim siab ntawm conical twin ntsia hlau extruder (CTSE) thiab ib qho ntsia hlau extruder (SSE) hinges ntawm daim ntawv thov tshwj xeeb thiab kev ua haujlwm. Rau cov ntawv thov xav tau kev sib xyaw ua ke zoo tshaj, txo qis kev ntxhov siab, txhim kho yaj ruaj khov, thiab muaj peev xwm los tuav cov ntaub ntawv nyuaj, CTSEs yog qhov kev xaiv zoo tshaj. Txawm li cas los xij, rau cov haujlwm ua haujlwm yooj yim thiab cov ntawv thov raug nqi, SSEs muab cov kev daws teeb meem thiab kev lag luam.

Xaus: Navigating Extruder Toj roob hauv pes

Kev xaiv ntawm conical ntxaib ntsia hlau extruder (CTSE) thiab ib qho ntsia hlau extruder (SSE) tsis yog ib qho loj-haum-tag nrho kev txiav txim siab. Ua tib zoo tshuaj xyuas cov ntawv thov tshwj xeeb, cov txheej txheem ua tiav, thiab kev txwv nyiaj txiag los txiav txim siab hom extruder uas tsim nyog tshaj plaws. Rau cov ntawv thov uas xav tau kev sib xyaw ua ke zoo tshaj, cov khoom lag luam zoo, thiab lub peev xwm los daws cov ntaub ntawv nyuaj yog qhov tseem ceeb, CTSEs tawm los ua qhov kev xaiv meej. Txawm li cas los xij, rau cov haujlwm ua haujlwm yooj yim thiab cov ntawv thov raug nqi, SSEs muab cov kev daws teeb meem siv tau thiab kev lag luam. Los ntawm kev nkag siab txog qhov muaj zog thiab kev txwv ntawm txhua hom extruder, cov txheej txheem tuaj yeem txiav txim siab paub tias ua kom zoo dua lawv cov haujlwm thiab ua tiav cov khoom zoo.

Post lub sij hawm: Jun-27-2024